Auto electronics

Informationalized Solution

R&D tools

Marketing

In-vehicle network communication and diagnostic testing

In-vehicle network communication, as a core component of modern automotive technology, is defined and its importance cannot be overlooked. Simply put, in-vehicle network communication refers to the process of data exchange and information sharing among various electronic control units (ECUs) within the vehicle, as well as between the vehicle and external devices, through specific communication protocols. This process is crucial for achieving the intelligence, connectivity, and electrification of vehicles.

Diagnostic testing plays a crucial role in in-vehicle network communication. Its primary objective is to ensure the stability and reliability of the in-vehicle network system, which is essential for ensuring the safety of vehicle operation. Through diagnostic testing, potential network communication faults can be identified and resolved promptly, thereby preventing accidents during operation. Additionally, diagnostic testing helps improve the performance and efficiency of vehicles. By conducting comprehensive checks on the in-vehicle network system, bottlenecks in network communication can be identified and optimized, enhancing the speed and stability of data transmission, thereby improving the overall performance of the vehicle. Vehicle development is a complex system engineering process that involves different development stages and testing phases (component level, system level, and vehicle level, etc.), with varying focuses at each testing stage.

Based on customer demand specifications, industry regulations, and our own testing experience and know-how, Polelink provides end-to-end services for the development of in-vehicle network communication and diagnostic testing systems, including the development of testing standards, implementation of testing scripts, and testing implementation. These services cover both Ethernet-based testing solutions and testing requirements for traditional in-vehicle networks (such as CAN/CAN FD/CAN XL/LIN/FlexRay buses).

In-vehicle Ethernet testing solutions

Introduction and Technical Features of the Solution

Polelink's in-vehicle Ethernet testing system, with core hardware and software components from German companies Vector, Rohde & Schwarz, Technica Engineering, and American company Spirent Communications, enables complete TC8 and OEM custom test content.

Platformization: The testing system is scalable and can be expanded to meet the testing requirements of different platform variants.

Process-oriented: Supports CI/CT (Continuous Integration/Continuous Testing) and comprehensive testing management processes, including test case management, data management, test task management, and test issue tracking management.

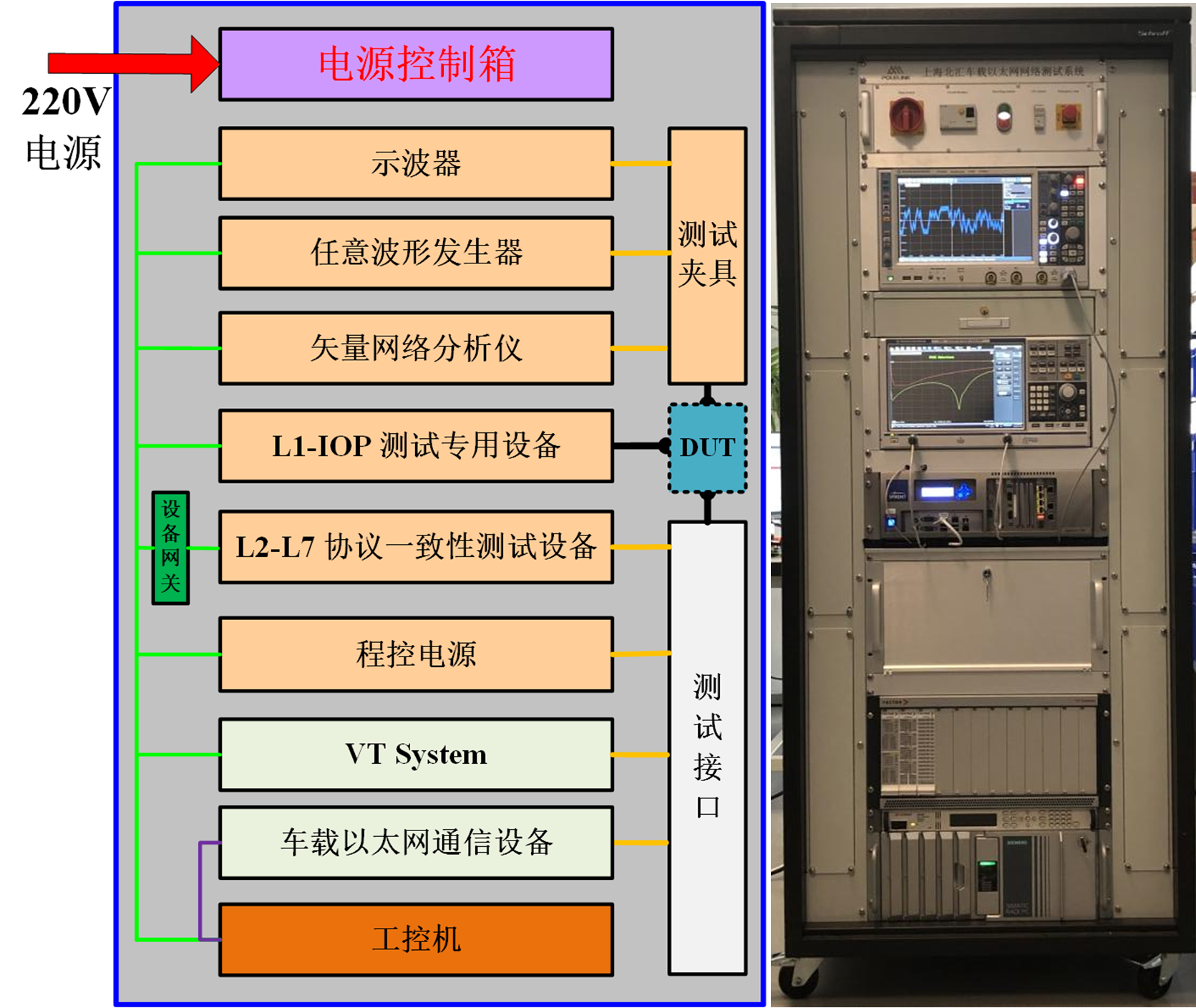

System Components

The structure and interfaces of the testing system are designed with modularity in mind, allowing for customization and tailoring of functional modules based on testing requirements.

The testing system comprises I/O boards, in-vehicle Ethernet communication devices, oscilloscopes, arbitrary waveform generators, vector network analyzers, L1-IOP (Layer 1 Interoperability) testing dedicated equipment, L2-L7 protocol compliance testing equipment, programmable power supplies, peripheral devices, as well as customized testing fixtures and interface modules.

Testing Functions

Polelink's in-vehicle Ethernet testing system meets the following testing requirements:

Node Ethernet Industry Conformance Testing (OPEN TC8)

OEM Customized Testing for Nodes:

- Component-level, System-level, and Vehicle-level Testing

- Communication Configuration Parameters

- Application Configuration Parameters

- Network and Node Management

- Diagnostic Protocols

- Diagnostic Flashing

- Robustness Testing

Gateway Testing:

- Gateway Functionality Testing

- Gateway Robustness Testing

- Gateway Performance Testing

- S2S (Switch-to-Switch) Testing

The software and functionalities included in the testing system are as follows:

> In-vehicle Ethernet L1-PMA Testing:

- Semi-automated testing supporting 10BASE-T1S, 100BASE-T1, 1000BASE-T1, MultiGBASE-T1 testing.

> In-vehicle Ethernet L1-IOP Testing:

- Automated testing.

> In-vehicle Ethernet L2-L7 Protocol Conformance Testing:

- Automated testing.

> In-vehicle Ethernet OEM Customized L5-L7 Testing:

- Environment configuration and test monitoring functionalities provided for testing.

> In-vehicle Ethernet Diagnostic Protocol Testing:

- Parameter configuration through importing database files to automatically generate test cases.

> In-vehicle Ethernet Diagnostic Flashing Testing:

- Programmable implementation.

> Network and Gateway Testing based on Polelink's PAVELINK.NETWORK/PAVELINK.TEST CENTER software:

- Parameter configuration through importing database files to automatically generate test cases. This software, based on template-based code generation, facilitates batch generation of test scripts to enhance automation testing efficiency.

> Continuous Integration/Continuous Testing (CI/CT) based on Polelink's PAVELINK.TEST CENTER platform:

- Core toolchain includes Jenkins, SVN/GitLab, JIRA, etc.

- Manages test devices, automatically generates test scripts during project execution, creates tasks and issues, tracks statuses, feedback, processing, and closure throughout the lifecycle.

- Provides services such as email notifications, statistical analysis reports, etc.

The CAN/CAN FD/CAN XL/LIN/FlexRay bus network and diagnostic testing solution

Solution Overview and Technical Features:

The automotive CAN/CAN FD/CAN XL/LIN/FlexRay bus automated testing system, with core hardware and software from Germany's VECTOR, enables comprehensive automated testing of CAN/CAN FD/CAN XL/LIN/FlexRay bus networks and diagnostics.

Automation: Following the development approach of the V-model, the system leverages communication/diagnostic databases to automatically generate test cases and execute tests, ensuring consistency and efficiency in testing.

Scalability: The testing system is scalable, allowing for expansion to meet the varied testing requirements of different platform variants.

Process-oriented: Supports Continuous Integration/Continuous Testing (CI/CT), facilitating a streamlined testing management process including test case management, data management, test task allocation, and test issue tracking management.

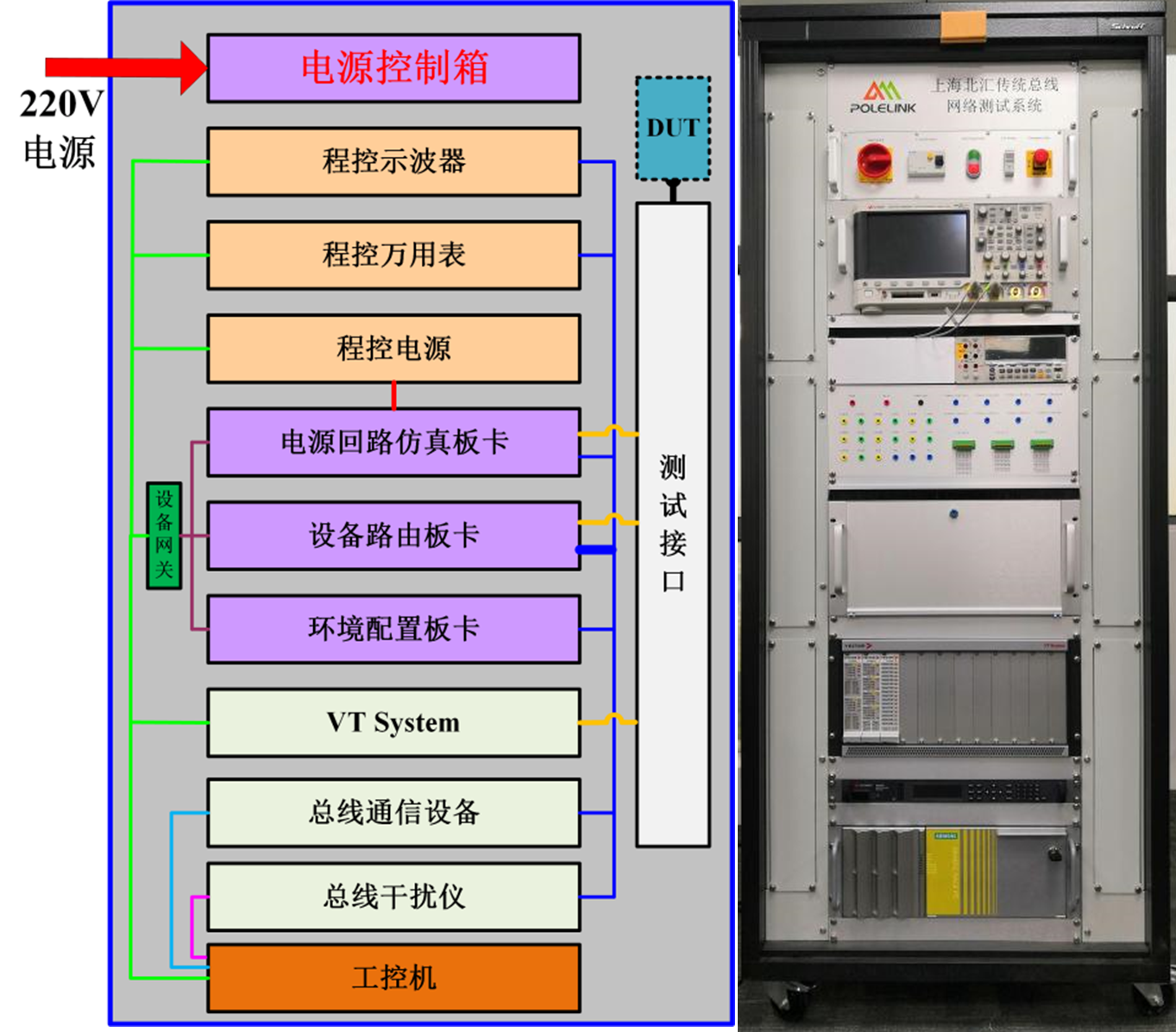

System components:

The structure and interfaces of the testing system are designed with a modular approach, allowing for the customization and tailoring of functional modules according to specific testing requirements.

The testing system's core is based on instruments from Vector's VT System, which includes I/O boards, bus disturbance generators, programmable oscilloscopes, programmable multimeters, programmable power supplies, as well as custom hardware and interface modules tailored to specific testing requirements and scenarios.

Testing Functions Details:

Polelink offers an automated testing system for automotive CAN/CAN FD/CAN XL/LIN/FlexRay buses, covering component-level, system-level, and vehicle-level testing, meeting the following requirements:

Network Testing for CAN/CAN FD/CAN XL/FlexRay:

- Physical Layer Testing

- Data Link Layer Testing

- Interaction Layer Testing

- Fault Tolerance Testing

- Network-related Diagnostics

- Network Management

LIN Network Testing:

- LIN Master Node and LIN Slave Node Testing

- Physical Layer Testing

- Data Link Layer Testing

- Fault Tolerance Testing

- Network Management

- Status Management

Diagnostic Testing for CAN/CAN FD/CAN XL/LIN/FlexRay:

- Diagnostic Protocol Testing

- Diagnostic Flashing

Gateway Routing Testing:

- Application Message Routing and Diagnostic Message Routing:

- CAN-CAN, CAN-CAN FD, CAN-CAN XL, CAN-LIN, CAN FD-LIN, CAN XL-LIN, FlexRay-CAN/CAN FD/LIN, etc.

Network Security Testing:

- SecOC, E2E, etc.

System-level and Vehicle-level Testing.

> The software and functionalities included in the testing system are as follows:

> Test Execution and Management:Based on Vector's CANoe software, providing environment configuration, test monitoring, and other functionalities.

> Diagnostic Protocol Testing:Utilizes Vector's CANoe.Diva software, configuring parameters by importing database files to automatically generate test cases.

> Diagnostic Flashing Testing:Implemented using Vector's CANoe CAPL programming.

> CAN/CAN FD/CAN XL/LIN/FlexRay Network, Gateway, and Network Security Testing:Based on Polelink's PAVELINK.NETWORK/PAVELINK.TEST CENTER software, configuring parameters by importing database files to automatically generate test cases. This software, utilizing template-based code generation, facilitates batch generation of test scripts, enhancing automation testing efficiency.

> Continuous Integration/Continuous Testing (CI/CT):Implemented using Polelink's PAVELINK.TEST CENTER platform, integrated with core tools such as Jenkins, SVN/GitLab, JIRA, etc. Manages test devices, automates test script generation during project execution, creates tasks and issues, tracks statuses, feedback, processing, and closure throughout the lifecycle, and provides functionalities such as email notifications, statistical analysis reports, etc.