Auto electronics

Informationalized Solution

R&D tools

Marketing

The Evolution of OTA Testing

Since last year, OTA (Over-the-Air) has gradually shifted from being a feature exclusive to a few "premium players" to a widely adopted function in the automotive industry. Both traditional and emerging OEMs have begun making layouts around OTA, and as a result, the development, testing, and application of OTA functionalities have flourished across the board.

We know that any vehicle feature is tested before mass production to verify its completeness, and OTA is no exception. OTA functionality involves almost all major domains of the vehicle, making its testing more complex and challenging. In previous OTA-related articles, we have already introduced OTA testing methods and key focus areas, and shared OTA testing solutions through real-world cases implemented by Polelink. As a pioneer in OTA testing, today, we continue to look at the new changes brought by the popularization of OTA functionalities in the entire OTA testing field.

Elevated Importance

Previously, OTA functionality was considered a bonus feature. However, in the coming years, it may become as essential as a smartphone's camera function—"I may not need to use it, but it can't be missing." From the investments made by major OEMs in the development of OTA-related functionalities, it is clear that the importance of OTA has further increased. Some manufacturers have even split it into a separate functional domain, highlighting the current significance of OTA. Naturally, as the guarantor of OTA functionality, the importance of OTA testing has also risen accordingly.

Further Compression of Development Cycles

The competition in the domestic automotive market has become increasingly fierce, and the development cycle of vehicles has been compressed significantly compared to previous years. All functional domains have had their development times reduced, but this change is particularly noticeable for OTA. Many vehicle functions are now gradually implemented after delivery, and the prerequisite for this is that the vehicle is equipped with OTA functionality. Therefore, it can be said that a reliable OTA function is the foundation for the subsequent activation of other functions, and OTA itself is a basic function directly experienced by users. As a result, the development cycle of OTA functionality is naturally compressed more severely.

Polelink's New Generation OTA Testing Solution

When you saw the title of this article, you probably started wondering why we are pushing for an upgrade to the OTA testing solution. The reason is simple: after completing the design of the first generation OTA automated/semi-automated testing solution, while actively promoting its implementation and providing excellent service to our customers, we have also been thinking about the next generation of OTA testing solutions. The first-generation solution addresses the question of whether or not OTA testing is possible, but it cannot meet our higher expectations for OTA testing. Additionally, more OEMs are showing interest in OTA testing, and the development of the industry has raised new demands on testing solutions. Based on these needs, we have conceptualized the next generation of testing solutions alongside the implementation of the first-generation solution. Compared to the previous generation, we focus on the following key aspects:

More Comprehensive Test Coverage

The new solution plans component-level, system-level, and vehicle-level testing in a unified manner, allowing component-level, system-level, and vehicle-level OTA testing to be covered within a single testing system, all managed by a unified management terminal. Additionally, we can adapt the testing platform to more hardware systems (racks, small onboard chassis, etc.).

Broader Testing Compatibility

In the new solution, we have abstracted the testing process, making it easier to configure and adjust. The OTA process often has subtle differences between different models, and in the new solution, these adjustments can be quickly adapted through configuration files, allowing for rapid adaptation to new models, shortening the development cycle, and improving the compatibility and efficiency of the testing system.

Greater System Expandability

Although the new testing solution is based on OTA testing, it is not limited to OTA testing. The unified interface brings greater freedom of expansion. As long as the same interface is followed, various tools, plugins, and hardware devices can be integrated into the testing system, becoming part of it to achieve different functions.

New Generation OTA Testing Solution

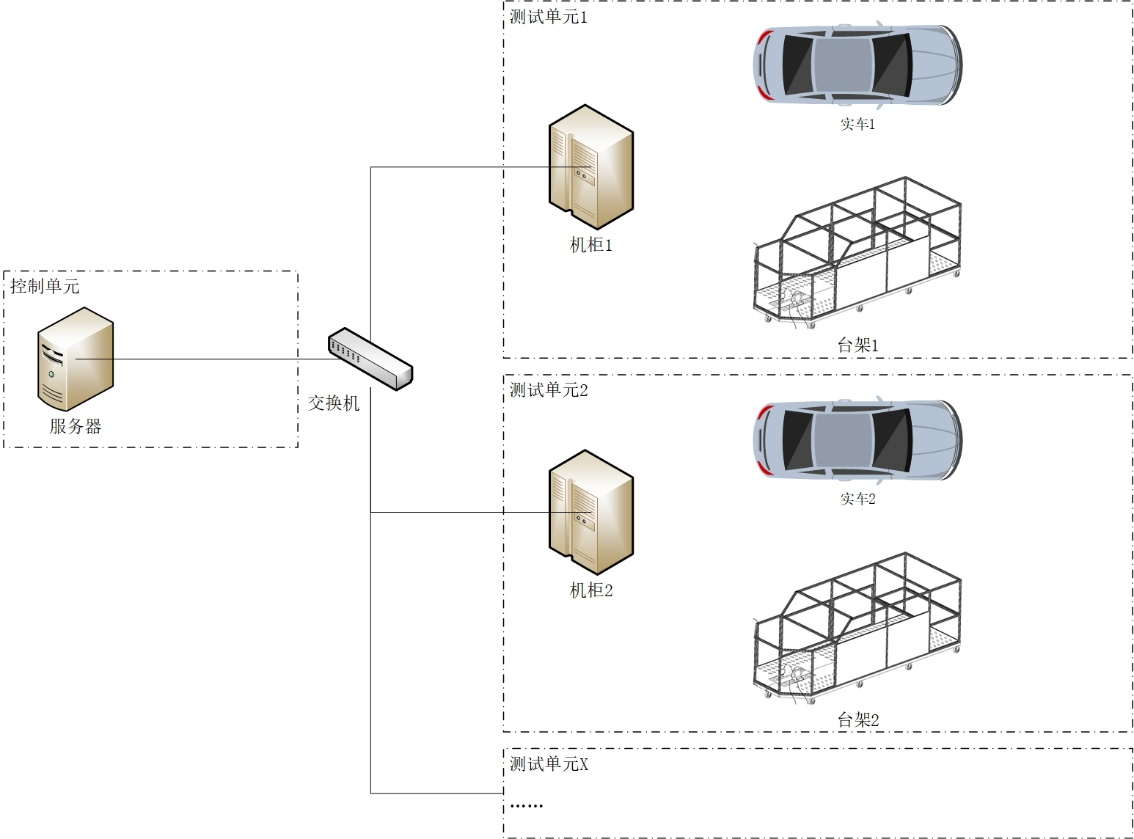

Polelink’s second-generation OTA testing solution is based on the first-generation solution and retains its complete vehicle electronic and electrical system simulation and testing capabilities. The overall architecture adopts a "1+N+3" structure: "1" represents a unified testing management platform **Pavelink**; "N" represents compatibility with various testing tools and hardware; and "3" represents the coverage of component, bench, and vehicle testing scenarios.

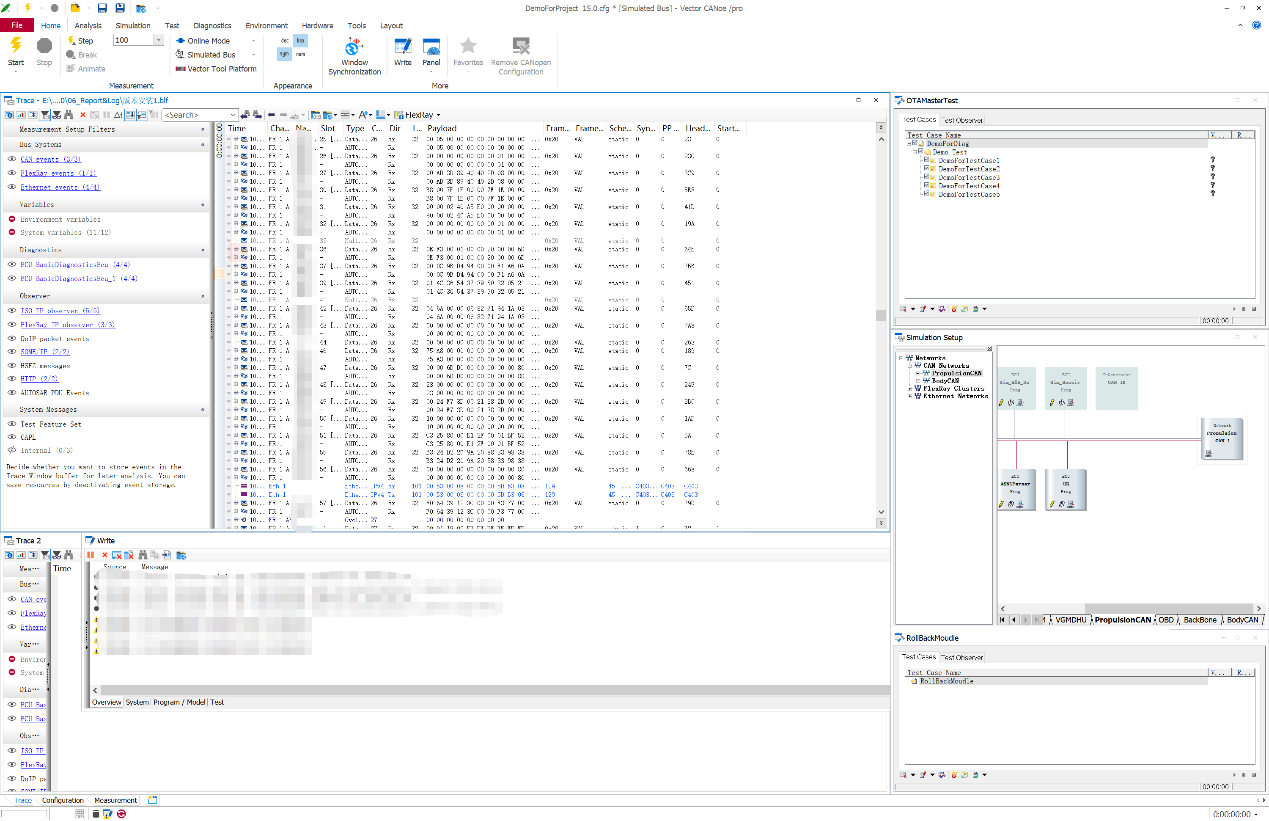

For those familiar with the first-generation testing solution, we resolved the issue of OTA testing availability by transforming OTA testing from “output-based black-box testing” into full-vehicle link monitoring and analysis, achieving “white-box testing.” Additionally, with years of technical accumulation, we have acquired the capability to simulate various in-vehicle signals, allowing us to test OTA core components separately from the vehicle, conduct subsystem-level testing, or even extract individual components for component-level testing. This enables early detection and correction of OTA issues.

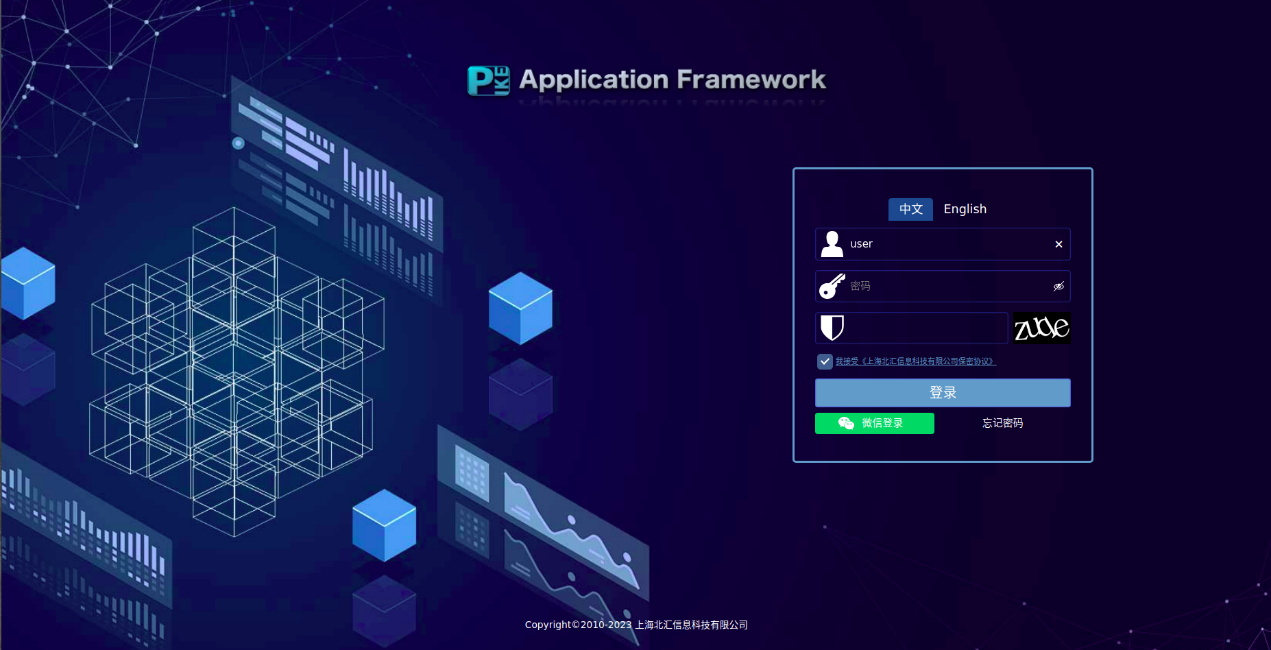

Pavelink, Polelink’s self-developed testing management platform, is the core of the entire solution. It handles the creation and management of testing tasks, the distribution and execution of test projects, the collection and statistics of test results, and the logging and archiving of test logs. Developed based on the server-client model, it enables remote server access, allowing real-time monitoring of testing activities without being physically present at the testing site. All test results and data are gathered on the server, enabling the platform to perform global monitoring, statistics, and evaluations of the overall testing situation. Additionally, the proxy engine embedded in the client provides a unified interface for various tools, allowing them to be integrated into the testing project management on the platform. Whether it’s CANoe projects, programmable devices, or self-developed tools and plugins, they can all be included as part of the testing process to achieve our testing objectives.

In terms of the testing environment, the new generation solution can operate on test benches, test racks, and small onboard testing systems, providing hardware support for component-level, system-level, and vehicle-level testing. Whether it’s a testing rack or an onboard system, Polelink can provide customized development based on specific needs, and corresponding adaptations can be made within the management platform to meet various special requirements of customers while maintaining generality.

In terms of automation, by deeply interfacing with the server provided by the customer, we can customize and develop an automatic control module for the server, enabling automated generation of test tasks, automatic distribution, real-time monitoring of background data, and more. This allows stress testing to be conducted continuously for 24 hours without human intervention, greatly improving testing efficiency.

Lastly, the standardized interface lays the foundation for the expansion of the management platform. Any module that meets the interface definition can be directly integrated into the testing logic, and the self-developed **CANoe Agent** proxy engine by Polelink can aggregate all instructions and perform interface conversion for use by different testing modules, ensuring that the system remains versatile and continuously upgradable.

Conclusion:

Polelink is committed to providing customers with better solutions, not only addressing the question of whether or not a problem exists but also offering more general, convenient, and comprehensive solutions from the customer’s perspective. For OTA testing, the seamless transition between the first and second generations of solutions reflects years of technical accumulation. We hope our solution can help more customers meet their OTA testing needs, while also contributing to the advancement of the entire domestic automotive industry.

If you are interested in our solution or have related testing needs, feel free to contact us for further technical discussions.